since 1850

Producing nets with passion and innovation, that's what we do.

Our story began in 1850 in Apulia when Eugenio Quartulli started the production of filters woven from plant fibres, used in the olive pressing process. That innovative product, made from reed yarn, allowed for obtaining a much larger amount of superior quality extra virgin oil that was unimaginable at that time.

Throughout our 170 years of history, we have relentlessly worked on product evolution while remaining true to our founder’s vision for the company:

PRODUCT INNOVATION + TECHNOLOGICAL INNOVATION =

PRODUCT QUALITY

to satisfy our customers even more.

Today, the production of nets and sheets takes place in our plant in Brindisi, where every step is meticulously supervised by our skilled technicians, starting from the selection of the raw material, HDPE granules, we use for all our products, and ending with custom weaving and packaging.

Our experience has led us to produce sound nets, and our imagination has led us to make one-of-a-kind nets

We manufacture nets and technical cloths in different measurements, sizes, and colours. In the many fields they are used in, our nets meet the needs of companies active in farming, construction, and processing of composites.

We are one of a few Italian netting manufacturers that also produce yarns from HDPE granules. Direct and assiduous control of all production stages ensures that our products are the best quality, to ensure that the solutions delivered are beyond our Clients’ expectations.

We use our testing lab and certified external organizations to prove compliance with the promised quality.

All production and management processes aim at customer satisfaction, and to this end we use a quality management system complying with EN ISO 9001:2015 standard that is periodically certified.

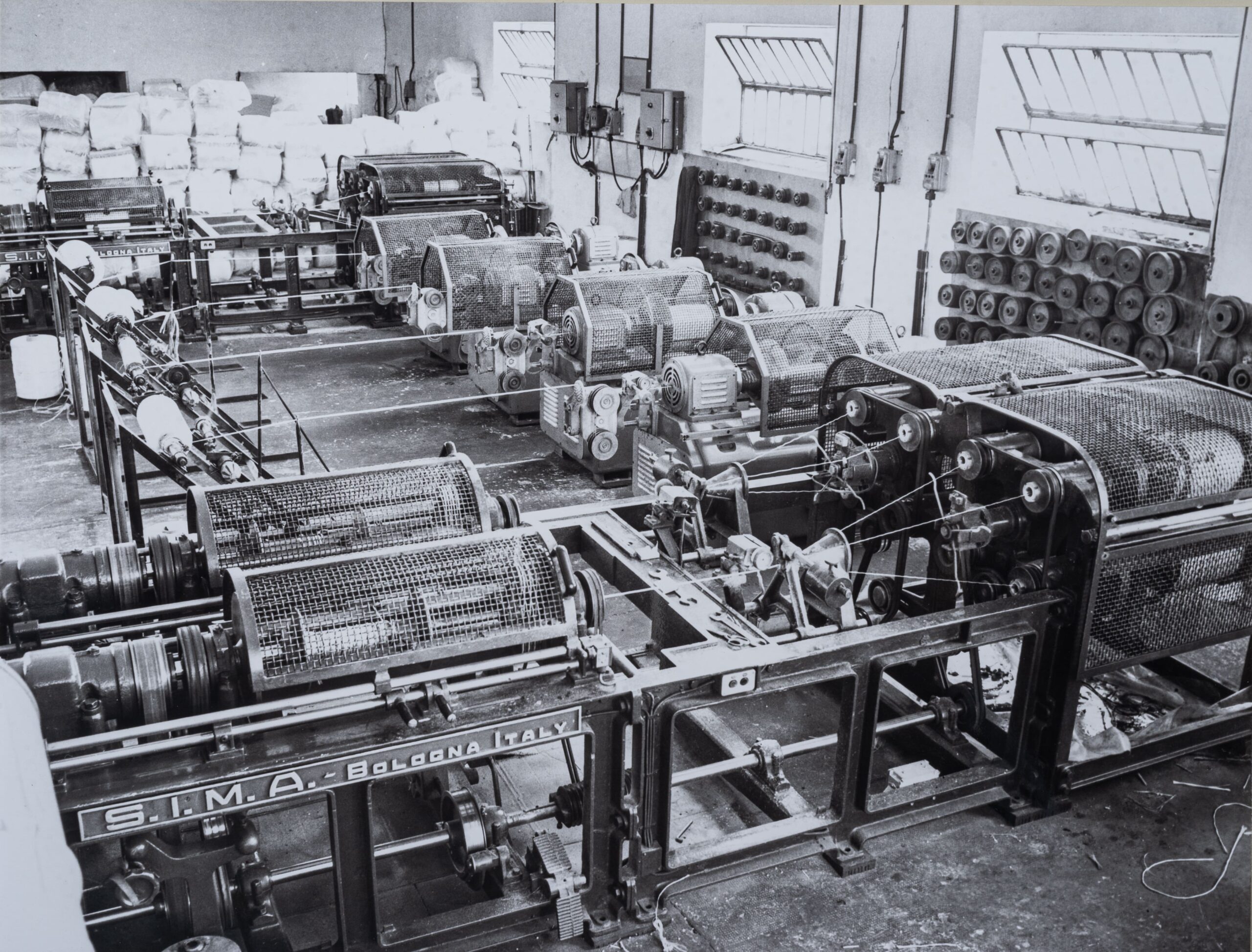

We use complex and technologically innovative production processes.

We invest an average of 10% of annual sales on the modernisation of facilities, to reduce fabric defects, to improve its inherent qualities, and to use less energy sources.

This focus allows us to always be on the cutting edge, to meet at best the expectations and varied needs for use in different technical fields, from construction with netting for making scaffolds safe, to farming with nets to protect crops, to the composites industry. We do not stop at these, however.

One of the reasons behind the success of our products is on time and fast deliveries.

Nets arrive at their destination at the time requested: 3-4 days after the order in Italy and 3-5 days elsewhere in the European Union.

This certainty allows our customers with low stocks to satisfy any request at any time and without any worries.

We offer a full range of nets and cloths for different sectors:

- FARMING: innovative agrotextiles, such as windbreak netting, shade nets, hail and rain protection nets, which are particularly valuable for protecting crops from the effects of climate change we are dealing with nowadays, but also nets for harvesting olives and nuts.

- BUILDING SITES: with technical fabrics used as dust barriers, construction site fences, and scaffold and fall protection nets.

- DIGITAL PRINTING: with nets that, in addition to protecting construction sites, are means of posting advertisements on work areas and beautifying them.

- COMPOSITES INDUSTRY: with multilayer fabrics that make vacuum-assisted resin transfer moulding (VARTM) processes used in the fabrication of marine hulls, drones, and in the wind power industry easier, faster, and cheaper.

We have always been attentive to details that go beyond the fabric. One of these is packaging.

With the goal of reducing overall dimensions, nets always reach their destination well wrapped and packaged in pressed bales or in coils wrapped with stretch film and palletized.

All plastic packaging used is obtained from the partial use of recycled raw materials.

OUR HISTORY

Since 1850 till now.

Our story began in 1850, thanks to Eugenio Quartulli who, in Apulia, Italy, started the production of woven filters made of vegetable fibres used for pressing olives. Since then, we have come a long way. We have done a lot of innovation and woven many nets and cloths for many different applications. Today we are here with our experience to provide your company with the right product at the right time.

Our plant in Brindisi, located near the most important motorway in Salento, covers over an area of 20,000 square metres, largely intended for the weaving and storage of raw materials and finished products.

Next to the production area is a plot of land, that is a very important area for us, covered by a natural forest, where we can enjoy a cool, healthy, relaxing moment accompanied by the scent of maritime pines.

Here is where we make our netting for construction sites, scaffold netting, nets for farming, safety nets, including sports nets, and netting for composite materials used in vacuum infusion process. We find a solution for every need, even customised, and designed by the Client.